FOR SALE:

The first “Pre-Production” unit: SN I-00

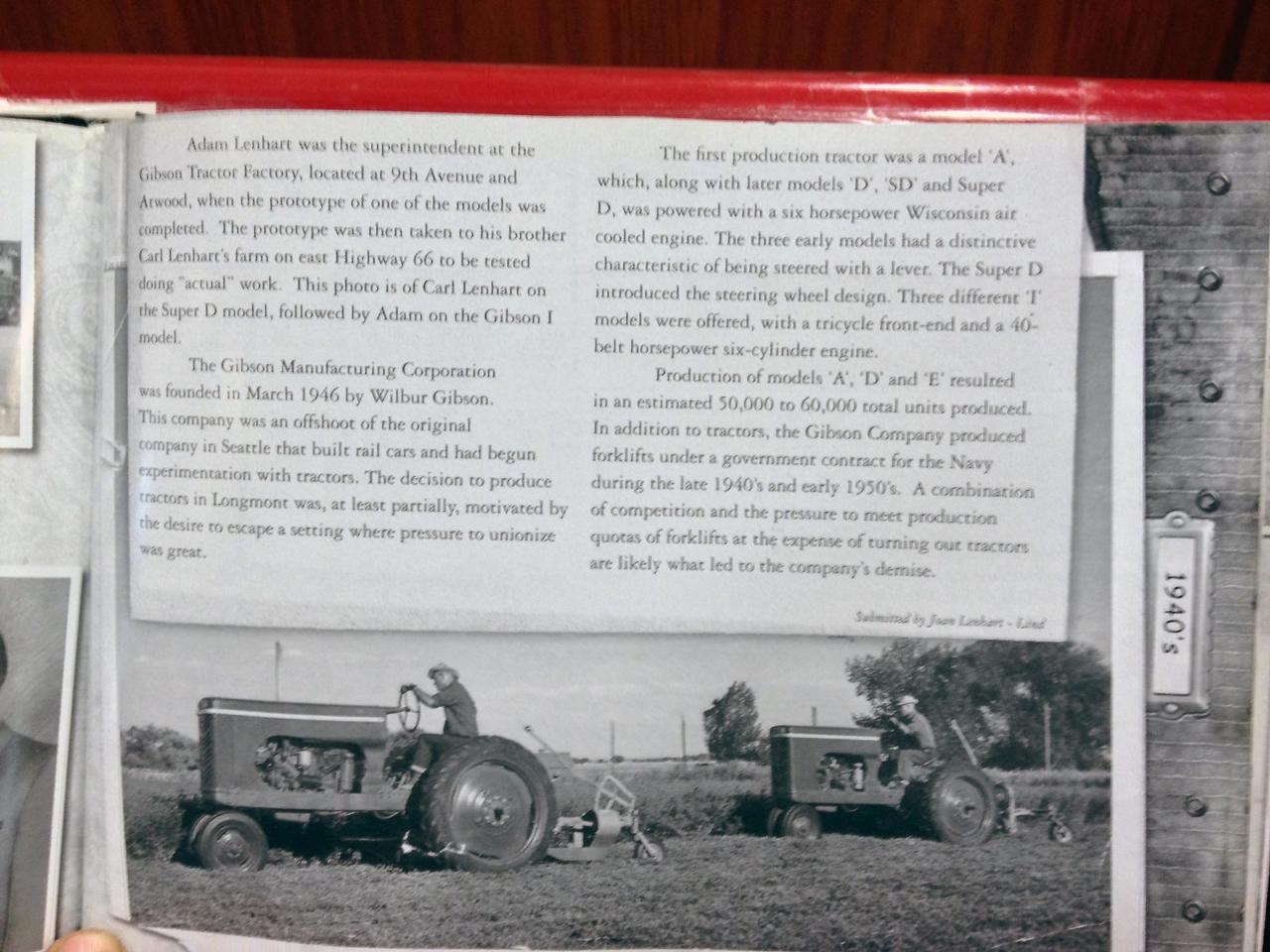

This tractor was manufactured in Longmont Colorado around 1948. Although the Gibson tractor company made some 500,000 garden size tractors, this was Gibson’s first and last attempt at a full sized tractor. One of the things Mr Gibson was famous for was his ability to find parts, when none were available, due to World War II. He often used rear ends and transmissions from other vehicles (new or re-manufactured I’m guessing) and modified them to fit his needs. He also had a foundry and full factory for mfg. other parts as well. I have restored a few of his works, and my hat will always be off to that man. I met his now late wife at the 50th anniversary show in Longmont, she was an angel at 95! ( I know a lot more about this particular tractor than I do about the Gibson Tractor Company so these dates, times and numbers may be a little off. Please feel free to check the various “Gibson Tractor club sites” for more accurate details). Also you can call me and i will tell you how to view more photos. go to gibsontractor dot (you know) for more photos.

I have included some photos of other Gibson I ser.#’s. so you can see how he stamped them on the frame rails. I personally have never seen a serial # for an I that was larger than 2000, so I don’t think very many were made. He always put the model name initial then ser. #….hence I- 1768, D- 72, H- 468…etc. and in our case “I 00”. I can’t say why there is no dash between the I and the 2 zeros like in the production units, but I can say several parts on this tractor were drilled, filled and then drilled again just a bit differently in order to obtain a proper fit, as they were learning just where all the major parts were going to align, after all this was the first one!

This tractor’s 12 year restoration project, employed nearly every professional technique available.

When we first acquired this piece it had been totally abandon as having no usefulness. It had no rubber, wheels, head, starter ,generator, manifolds, water-pump, distributor, electrics, or any other part that could be removed easily! It was nearly completely buried in the sand, the block was open (no head) the transmission-rear-end was full of sand and rust. Just finding all the necessary parts, pistons, rings, bearings, seals, brake parts, hubs, wheels, tires, u-joints, tie rod ends,…etc…etc… took several years. Many parts like brake bands, water-pump shaft, brass gear bushings, various other bushings had to be machined from views of old parts, or parts manual views, and or, worn out or partially missing parts. If it weren’t for the fact that it was in fact the first pre production model…well it would not be here now.

We had to sand blast every single part of the tractor. All new bearings, gaskets and seals in the engine, transmission, pulley housing, rear-end, rear axels inner and outer, steering u-joints, pretty much every bearing, gasket and seal on the entire tractor! It drips less than most brand new tractors! All new drive shaft parts, as well as both brake bands. The gas tank was chemically cleaned. The seat got new springs with all new upholstery and stuffing.

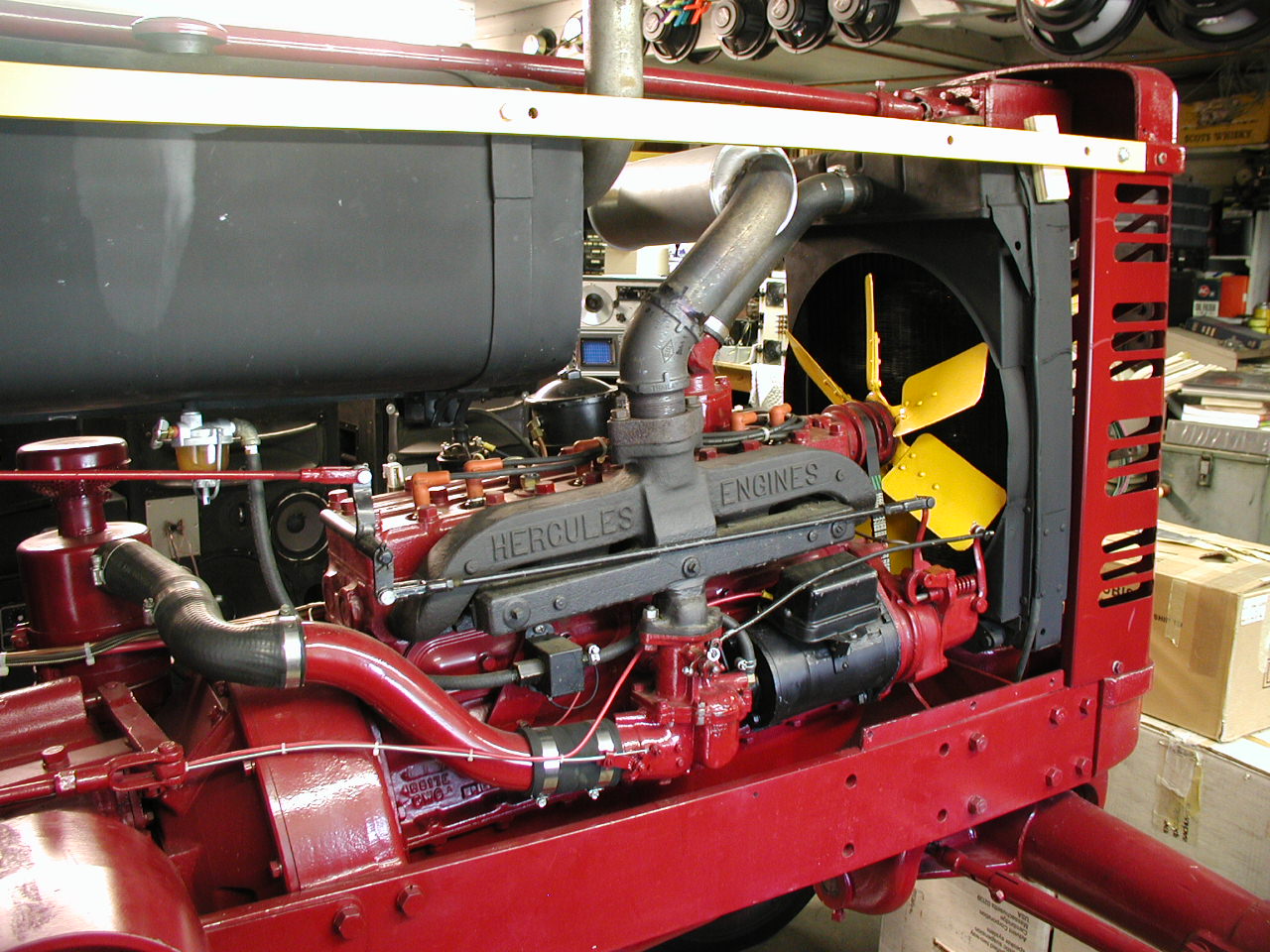

The engine crank had to be Flame-sprayed as well as several shafts in the transmission-rear-end. The engine has been Acid boiled, bored 60 over (per speck with Hercules), balanced, hardened valve seats, and the head milled .030. All new bearings, rings, seals, pumps. new water-pump shaft, completely restored governor, carburetor, distributor, air cleaner, radiator, belts hoses. The original engine produced about 32 belt-horsepower, after all of our work, and burning modern gas, it now produces 48 hp @ the PTO. ( with no sacrifice to the longevity of the engine)

The entire electrical system is 12 volt negative ground. The “gear driven” generator was rewound and fitted with a “3 relay” regulator, to prevent generator burnout and or battery overcharging. The starter has been rewound and completely rebuilt as well. All new gauges, cigarette lighter, hazard lights, (with flasher), head lights, rear light, fuel pump,and all wiring is new.

All of the sheet metal damage was filled with welding or brass…no bondo!!! Everything was double-primed, wet sanded, and three coats of hardened finish paint. The colors were generated by the original formulas. The seat ( we were able to trace to a city bus from that era) is the original seat Mr. Gibson put on this tractor, as it still had enough faint ruminants of the “Gibson logo” on the seat “sheet-metal” back for us to analyze and have decals made. It seems all of the later production units had a normal “spring and steel bucket” seat, so I am guessing he wanted a comfy ride while he was doing his tests, maybe it just looked better at the state fair….lol.

It has been a real show stopper, and marvelous parade piece…Its always garaged, and last year I even pulled it in an antique tractor pull—flawless pull! It beat everything except those hot-rod Olivers!

Besides the nearly $35,000 cash, 12 years of effort and all that love….it is time for a new owner..YOU need to have this incredible piece in your collection.

I have nothing to hide… ask me anything…. We will deliver to a major airport near you for a minimal fee. (lower 48….$500.00)

Thank you for your time,

Steve

Cell # 303-907-9078